Touch panels play a pivotal role in industrial applications, offering a streamlined interface that enhances efficiency and control.

In industrial settings, where precision, speed, and real-time monitoring are paramount, touch panels provide an intuitive and responsive means of interaction.

By eliminating the need for traditional input devices, such as keyboards or mice, touch panels reduce clutter and simplify operation, enabling seamless control of machinery, processes, and data visualization.

The versatility of touch technology empowers workers to navigate complex systems, monitor equipment, and execute commands swiftly, fostering a more agile and productive industrial environment.

Tips for Touch Screen Industrial Monitor Maintenance

Maintaining touchscreen industrial monitors is crucial for ensuring optimal performance and longevity in demanding industrial environments.

Implementing proactive maintenance practices can prevent issues and extend the lifespan of these critical components.

Regular Cleaning

Frequent cleaning of touch screens is essential to remove dirt, dust, and contaminants that can affect responsiveness.

Use a soft, lint-free cloth and a gentle cleaning solution approved for electronic displays.

Calibration Check

Regularly check and recalibrate touch screens to ensure accurate touch recognition. Calibration drift can occur over time, impacting the precision of touch input.

Follow your touch screen manufacturer guidelines for calibration procedures.

Protective Measures

Consider installing screen protectors or rugged overlays to shield touch screens from scratches, impacts, and harsh environmental conditions.

These protective measures can safeguard the display and maintain optimal functionality.

Temperature and Humidity Control

Monitor and control the temperature and humidity levels in industrial environments. Extreme conditions can affect touchscreen performance.

Ensure that the operating conditions align with the manufacturer’s specifications.

Update Firmware

Stay updated with the latest firmware releases from the manufacturer.

Firmware updates may include improvements in touchscreen performance, bug fixes, and compatibility enhancements.

Regularly applying updates can enhance functionality.

Inspect Wiring and Connections

Regularly inspect wiring and connections to identify any signs of wear, damage, or loose connections.

Faulty wiring can lead to erratic touchscreen behavior.

Ensure all cables are securely connected.

Emergency Shutdown Procedures

Establish emergency shutdown procedures to protect touch screens during unexpected events, such as power surges or equipment malfunctions.

Implementing shutdown protocols can prevent damage to the touch screen and associated components.

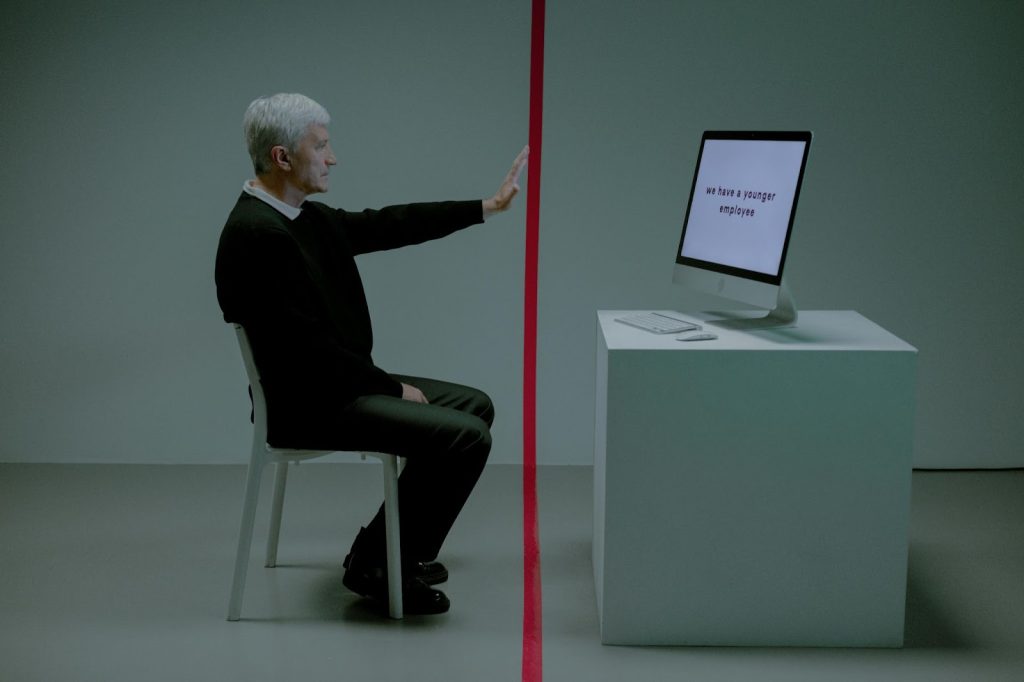

Employee Training

Train employees on proper touchscreen usage and maintenance practices.

Educate them about the importance of gentle touch, proper cleaning techniques, and adherence to operating guidelines.

Well-informed users contribute to the longevity of touchscreen monitors.

Troubleshooting Industrial Touchscreen PC Problems

Industrial touchscreen PCs play a critical role in various manufacturing and automation processes.

When issues arise, effective troubleshooting is essential to minimize downtime and maintain operational efficiency.

Here are common problems and troubleshooting steps for industrial touchscreen PCs:

| Industrial Touch Screen Problem | Troubleshooting Tips |

| Unresponsive Touchscreen | Check for physical damage on the screen;Verify proper calibration; recalibrate if necessary;Inspect and clean the touchscreen surface to remove debris. |

| Erratic Touch Behavior | Examine for nearby electromagnetic interference sources;Confirm proper grounding to eliminate electrical noise;Check for static electricity buildup; use anti-static measures. |

| Display Issues | Inspect video cables for damage or loose connections;Adjust display settings, resolution, and orientation;Test with an alternate monitor to isolate PC or display issues. |

| Hardware Failures | Monitor system temperatures to prevent overheating;Check the power supply and connections for stability;Inspect internal components for signs of damage or wear. |

| Software Glitches | Update device drivers and operating system;Scan for malware or software conflicts;Perform a system restore to a stable configuration. |

| Calibration Drift | Regularly recalibrate the touchscreen to maintain accuracy;Ensure that the environmental conditions align with specifications;Implement software updates that address calibration issues. |

| Intermittent Connectivity | Inspect network cables and connections;Verify network settings and IP configurations;Consider using redundant network connections for critical applications. |

| Slow Performance | Check for background processes consuming resources;Increase RAM or upgrade hardware components if necessary;Optimize software settings for efficient performance. |

| Malfunctioning USB Ports | Test with different USB devices to identify port-specific issues;Update USB drivers and firmware;Inspect for physical damage or foreign objects in USB ports. |

| Failure to Boot | Inspect power supply and connections;Verify the integrity of the operating system;Perform hardware diagnostics to identify faulty components. |

Key Takeaway

Addressing and resolving issues with industrial touchscreen PCs is crucial for maintaining seamless operations in manufacturing and automation settings.

From unresponsive touchscreens to software glitches, a systematic troubleshooting approach helps minimize downtime and ensures optimal performance.

Regular maintenance, timely updates, and skilled professional intervention contribute to the reliability and longevity of industrial touchscreen PC systems, ultimately enhancing efficiency in industrial applications.